While there is a lot of information and practical advice on the safe use and maintenance of forklifts and other plant equipment used in the workplace, there is one persistent question that will often be asked of many safety practitioners:

“Do we really need to do daily checks on our forklifts and other equipment?”

The answer is almost always a resounding, yes! However, each state-based safety regulator has their own guidance material on these matters, not surprisingly, so does Safe Work Australia. The abundance of guidance on this topic mostly specifies the same requirements to conduct pre-use checks / inspections.

Despite the universally understood need for pre-use checks, it is common for an operator to retort:

“But it was in good order when I finished using it yesterday, why do I need to check it again?”

It should be no surprise that a Person Conducting a Business or Undertaking (PCBU) has a primary duty of care to ensure, so far as is reasonably practicable, the health and safety of workers and others affected by the conduct of their undertaking or work. Specific duties are imposed when a PCBU manages or controls workplaces, or fixtures, fittings or plant at workplaces.

It is key that a PCBU has a system of management for controlling the risks associated with the use of plant in the workplace. Scheduled inspections and checks of the plant are critical to the control and safe use of plant and equipment. These inspections must be documented and will be scheduled across a mix of daily (pre-start), weekly, monthly, quarterly and annual. Some inspections will be based on time and some the frequency of use. In all cases the equipment supplier or manufacturer’s guidelines must, as a minimum, be followed. Safe Work Australia’s Model Code of Practice: Managing Risks of Plant in the Workplace highlights the importance of regular checks and maintenance to ensure the safety of any plant equipment used in the workplace.

Pre-start checks are a key component to managing the safe use of plant. Inspecting plant equipment before use helps to identify any hazards, faults or issues that could impact the equipment safety. The pre-start check will:

- Confirm the Equipment is Safe to Operate, or/and;

- Help Identify Hazards;

- Reduce Possible Equipment Breakdowns;

- Assist Meeting Compliance Obligation; and

- Helps Ensure Operator Safety.

Below are but a few of the interlocking obligations required for daily checks on plant equipment, including forklifts.

Victorian OHS Regulations 2017;

- r105 – Use of plant: An employer must ensure that: (a) plant is inspected to the extent necessary to ensure that any risk associated with the use of the plant is monitored.

- r106 – Record of inspection and maintenance: An employer must keep a record of any inspection and maintenance carried out on the plant for the period that the employer or self-employed person has management or control of the plant

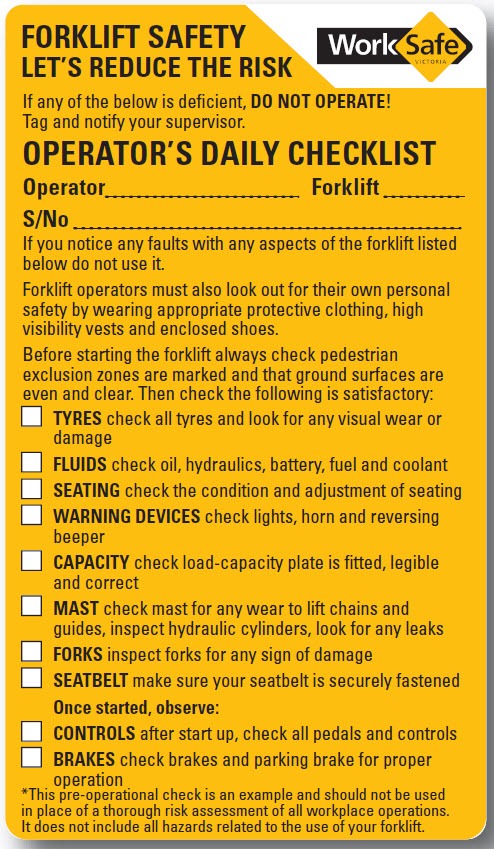

Each state has their own document requiring daily checks on forklifts. These daily checks are specified because the operation of forklifts is considered high risk work. Most of the states follow the requirements specified in the Australian Standard AS 2359.2, ISO 3691, Powered industrial trucks, Part 2: Operations. The below summarises the overall requirements:

Forklifts and any attachments must be regularly inspected and maintained to control risks associated with their use. A pre-operation inspection should be done in accordance with the manufacturer’s recommendations:

- at the start of each shift

- before first daily use

- when there is a change of operator.

Defects need to be reported. Have a system in place to lock out the forklift or any attachment from service if a defect is identified that makes the forklift unsafe for use.

PRE-OPERATING CHECK

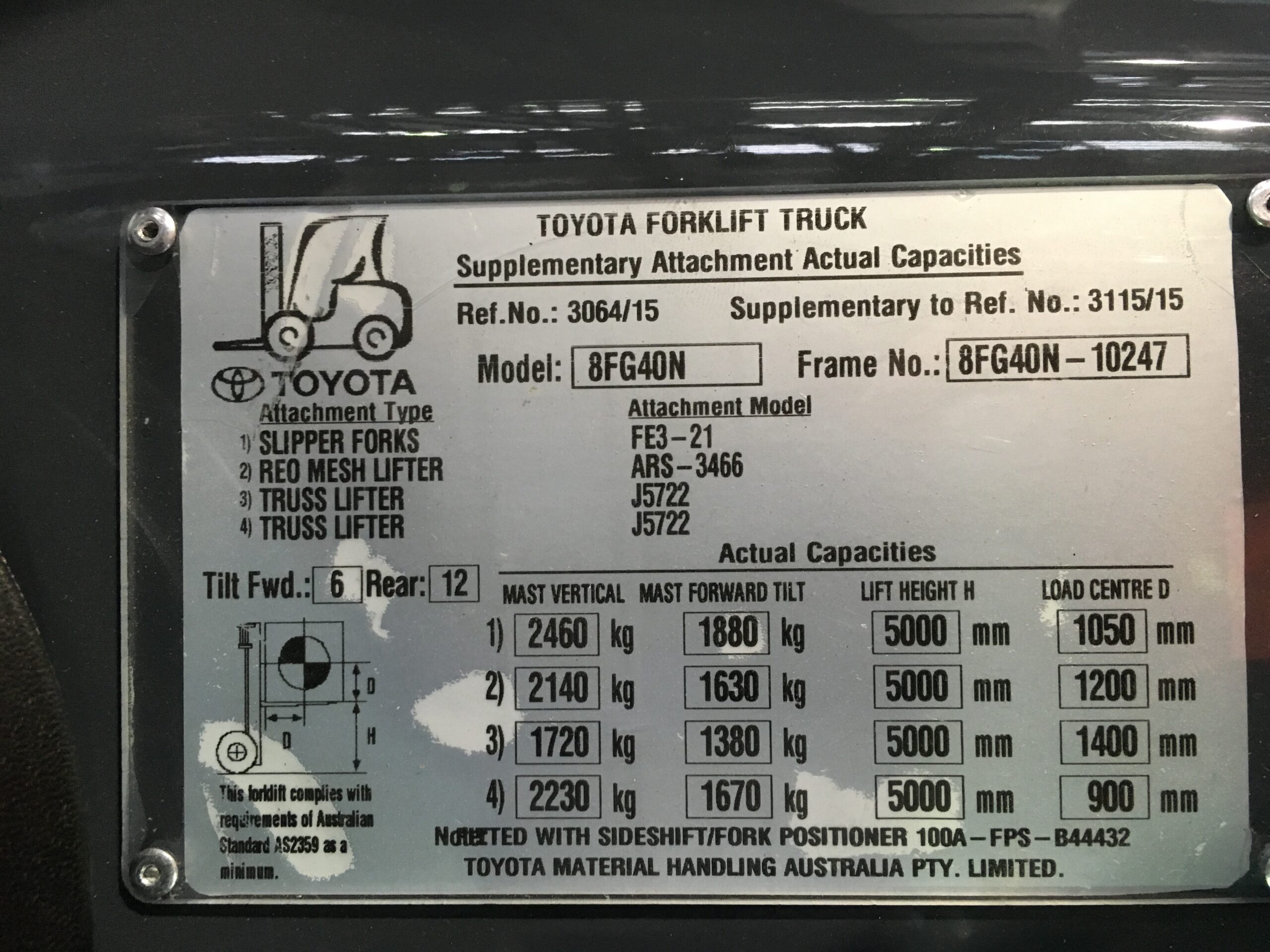

The user of a truck shall ensure that each operator has an understanding of the lifting capacities of the truck and any attachments that are to be used with it, and that the truck is capable of safely lifting all loads that will be required of it.

Pre-operating checks are aimed at ensuring a truck is in a fit condition to be used. The intent of this Section is that the following inspections be carried out by the operator, or by a competent person(s). Prior to use, if the operator does not perform these checks the operator shall sight evidence that the checks have been performed. Confine testing to an authorized area where safe conditions exist and there are no personnel in the vicinity.

Prior to the commencement of each working day or shift the following inspections shall be performed and a record shall be kept of these checks:

(a) That nameplates and markings are legible.

(b) That any attachments that are to be used are approved for use with that truck and are identified on the truck.

(c) That the condition and mounting of any attachments fitted is satisfactory.

(d) That lift and tilt systems including security systems, hoses, chains, cable and limit switches are serviceable.

(e) That the brakes, steering, controls, lights and warning devices operate effectively.

(f) That safety systems are operating effectively.

(g) That controls are clearly labelled and functioning.

(h) That the wear condition of each wheel and tyre, and inflation pressure of pneumatic tyres if fitted are within acceptable limits.

(i) That fluid levels, e.g. engine oil, brake fluid, hydraulic oil and coolant, are correct.

(j) The operator restraint (seatbelt) is in good condition.

(k) That fork arms (tynes) including their mounting are not unacceptably distorted or damaged.

(l) That seat(s) are secured and in good order.

(m) That bonnet, hood and battery retainers are in place.

(n) That battery cables and plug are not damaged.

(o) That any screens or mirrors used for vision are clean and not damaged.

(p) That the orientation of the gas cylinder is correct.

(q) That the securing of the gas cylinder and hose as well as the condition of the cylinder, hose and coupling are satisfactory.

(r) That any special features or options on the truck are performing satisfactorily.

NOTE: All operator manuals should remain with the truck.

The below links give detailed explanations of the requirements for detailed pre-start and scheduled inspections on plant equipment including forklifts:

- Safe Work Australia, Model Code of Practice: Managing Risks of Plant in the Workplace

- SafeWork NSW, Guide to Inspecting and Maintaining Plant

- SafeWork NSW, Code of Practice – Managing the Risks of Plant in the Workplace

- SafeWork SA, Managing Plant

- WorkSafe QLD, Code of Practice – Managing the Risks of Plant in the Workplace

- WorkSafe TAS, Plant Inspections

- WorkSafe Victoria, Compliance Code – Plant

- WorkSafe Victoria, Forklift Daily Checks

There is no doubt that the requirements, from many sources, mandate the pre-use daily checking or inspections of plant equipment, including forklifts. Where the plant includes critical safety components to protect operator safety, these results of these checks should be recorded and the records kept.

Having a system in place to manage plant equipment is an important obligation and helps keep operators safe.

Follow FTMA Australia for Industry News and Updates

Our Principal Partners